You won't find any "worses" here, on the contrary, we constantly develop and introduce new "betters" ones.

It is widely known that a number of manufacturers and companies put in their products intentionally, perhaps unintentionally and perhaps out of negligence, so-called "worses". It is a function, a property, a low-quality part, or a malfunctioning one, which must naturally go away and the user will be forced to deal with service, repair, or even the purchase of new goods...

This is not how we work at Motúčka (Mobarrow)!

Our motto is "The Mobarrow will be an object of inheritance from father to son and from grandfather to grandson", so we also manufacture our products so that they last as long as possible. The "betters" we are constantly devising and introducing help us to do this. We would like to introduce some of them to you.

- Quality paint/frame color:

In 2022, we acquired, among other things, our own powder coating plant, thanks to which we can guarantee that even the basic design of the frames of our Mobarrow will last a really long time without degradation and other inconveniences. We had a test done by a specialized company with 50 years of activity on the European market, and what was the result?

The test was carried out in a salt chamber for 480 hours and the result is that the durability of our surface treatment of the frames is over 15 years!

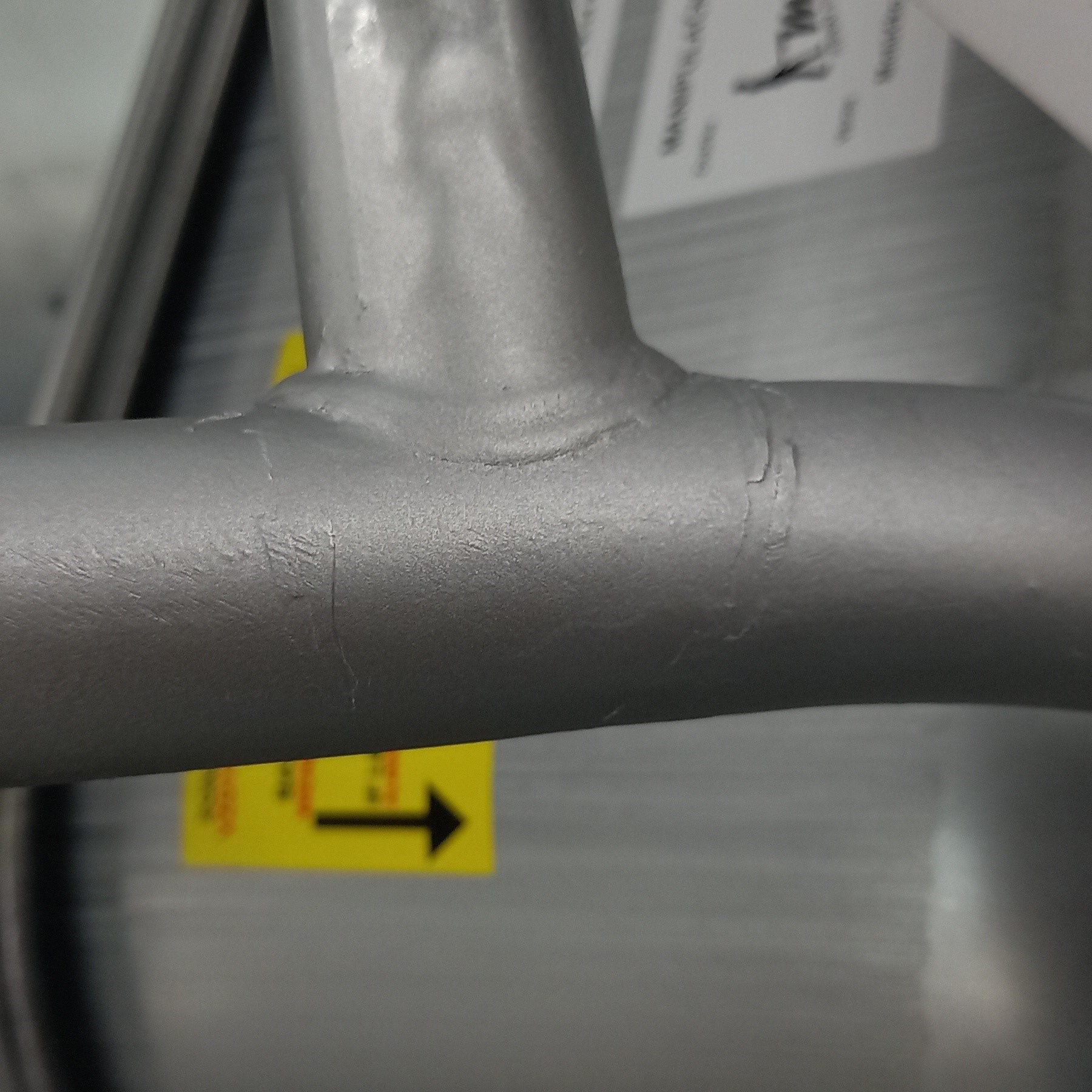

- Hot-dip galvanized frame treatment, ultimate frame protection:

Of course, there are users who will use Mobarrow in demanding conditions and the standard paint/paint is not enough for them, they want more and to be sure. From there, we have a variant with hot-dip galvanizing, which, of course, must be done by specialized companies.

Advantage: this design has a measured resistance of 25 years and more! It is also more resistant to physical damage.

Disadvantage: This process leaves marks on the surface that appear to be worn, with appearance defects, etc. However, this is not a defect that affects the function and quality of the treatment, but the possibilities of the hot-dip galvanizing technology. In short, steel cannot look like wood and hot zinc like paint.

- Drivers that work easily and in every situation:

We have received some reports that when using the Mobarrow for a long time, some users have sore thumbs and palms because the controller is too stiff. We responded to it and now from 5/2023 we have a new version of the controller, which is really easy and does not hurt even when working with Mobarrow for the longest time.

We put the controller on a fixture that regularly pressed it several times per second and the controller worked after an incredible 11,100,319 presses! After that, it was not the controller that failed, but the microswitch, it was easily replaced and the controller continued to work. It got over 18 million hits.

However, we did not end there... We know that those who work with Mobarrow work even in the rain, when there is mud and they transport various materials. So we improved the controllers again and performed a test where it is placed on a jig that constantly presses it and gradually water is poured over it, sand and dirt are poured on it. And the result? And the result? And again an almost unbelievable 11 million switches.

- Freewheel with steel insert:

The Mobarrow has a gearbox developed and manufactured by us, including steel wheels and a freewheel. Since it happens that after driving hundreds of kilometers, the freewheel can wear out and need to be replaced, we proposed an improvement where this freewheel will be supplemented with a steel insert and thus no replacement will be necessary. Implemented from October 2023.